We are proud to represent Boschman Package Development. Based in the Netherlands, Boschman has been a leading high-tech player in the semiconductor packaging equipment industry since 1987.

Package Development by Boschman offers package technology research, package development, qualification, prototyping as well as small to medium volume manufacturing services. They can manufacture products in quantities of 10 to a few thousands using manual or semi-automatic processes. These parts can be used for qualification purposes and first end-user sampling. For small/medium volume production, they offer production possibilities of a few thousand, to a maximum of 50,000 products per month.

Boschman serves the automotive, consumer, industrial, medical, optical and power markets offering their core technologies including:

- Film Assist Molding Technology with Dynamic Insert Technology

- Ag Sintering with Dynamic Insert Technology

- Through Polymer Via (TPV)

Boschman Package Development offers a unique highly integrated approach resulting in the most effective packaging solution in the shortest time to market possible.

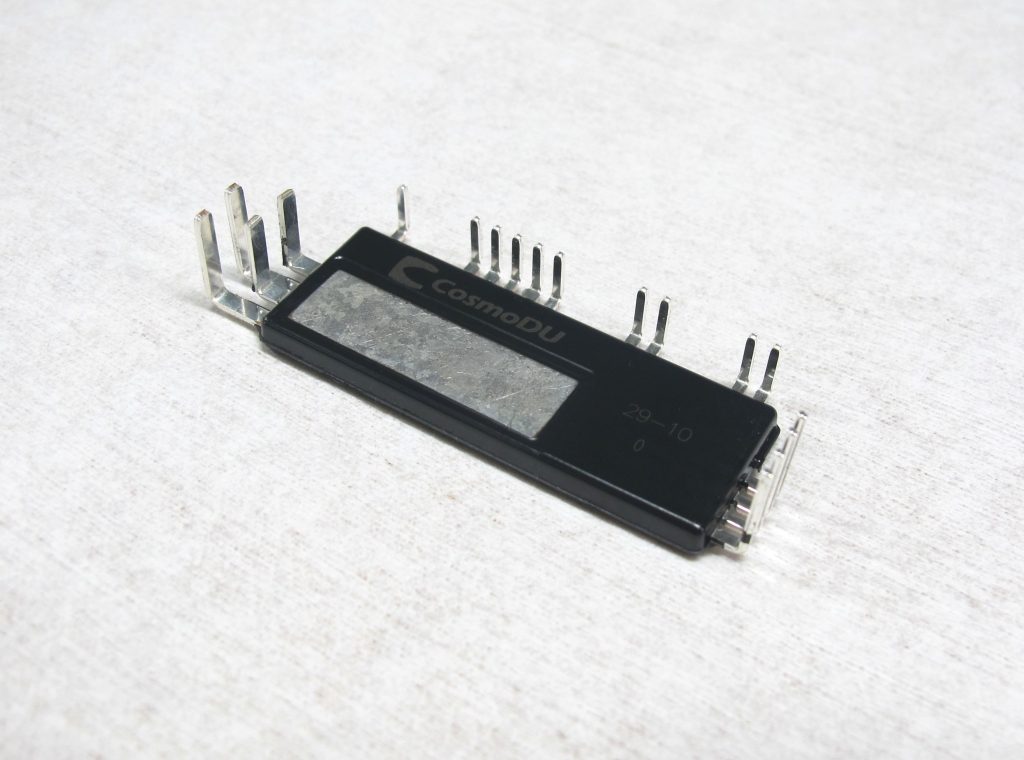

Boschman Participates in Innovative CosmoDU Project

A PENTA funded project called CosmoDU was recently completed with Boschman among its partners. The project was envisioned by EUREKA which is a consortium managed by AENEAS – an industrial association in the EU that is dedicated to partnership and fostering technology development and growth in the area of electronics value chain. CosmoDU brings intelligent devices to bear on electric drive technology providing self-learning capabilities for these systems. The smart intelligent electric drives developed within CosmoDU will be THE enablers for next level technologies in the field. These drives will increase manufacturing flexibility, maximize system availability, and can even learn and communicate.

“CosmoDU has developed the hardware platform of next-generation drive units, where sensors, signal processing, secure communication and control and power electronics have been directly integrated in the housing of the motor. This new drive unit uses its self-learning capabilities to adjust and improve its performance.” – https://penta-eureka.eu/project-overview/penta-call-1/cosmodu/

Trends in Power Modules

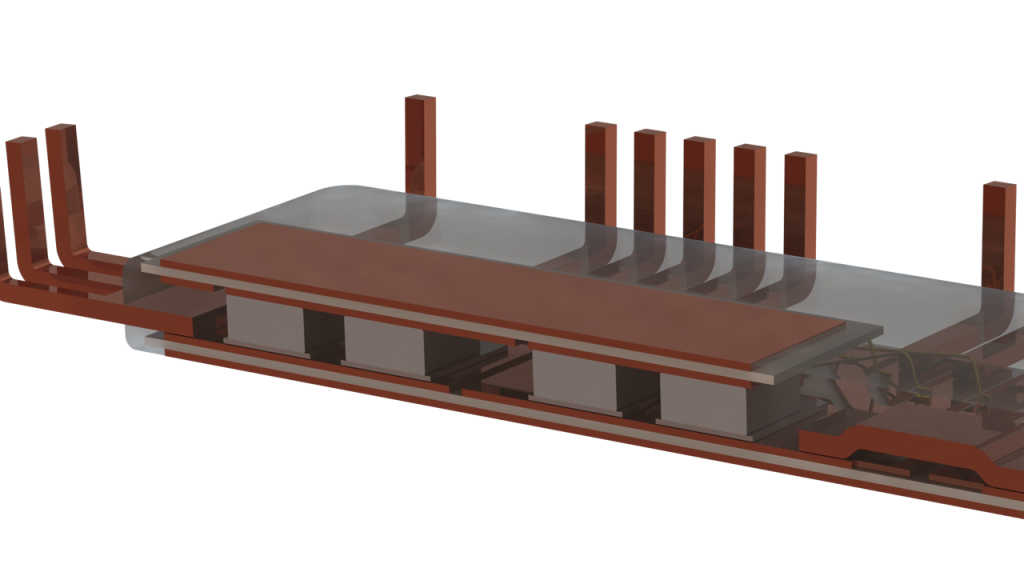

There is a shifting landscape in the power electronics supply chain. Customers are interested in moving from big power units with silicone gel and big plastic housings to high-density power units particularly the discrete type packages combined into an inverter. OEMs are driving these developments – for example Tesla who took a revolutionary approach integrating fully sintered next generation inverters. More and more we are seeing a trend to 2-sided cooling instead of one side, due to the better performance of the silicone die.

CosmoDU: DSC Module with Sintered SiC Mosfets Inside

As part of the CosmoDU project Boschman Package Development designed and built an innovative double-sided cooled silicon carbide (SiC) power module.

This example of Boschman’s work demonstrates the depth of their processes and the quality of their work. Boschman’s unique approach is not the cheapest or fastest – but does produce the highest-quality end-result. As an independent firm working with many different customers they are exposed to a wide range of ideas and concepts and are constantly developing on the fly. The best ideas are born through collaboration with customers and Boschman’s customers benefit from their wide-ranging experience.

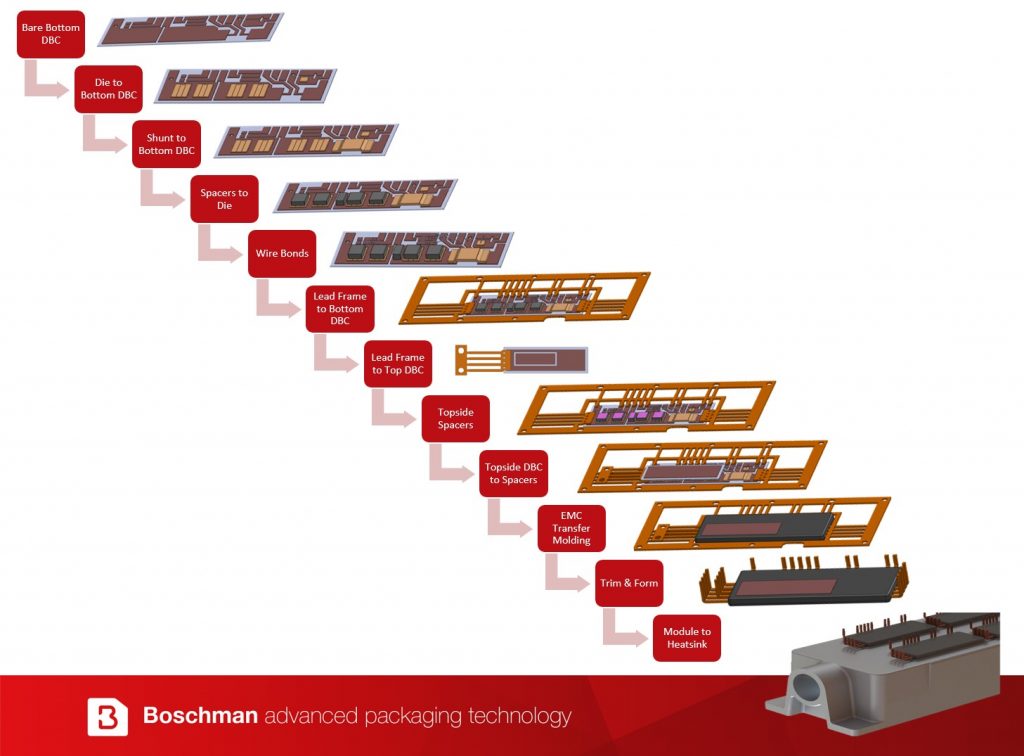

CosmoDU Package Process Flow

The process flow for this project shows the build-up of the package. The inverter is integrated into the motor (for industrial use) with bottom and top sides exposed. The package can be sintered to a cooling unit.

Put Boschman Package Development to work for you! Their wide-ranging experience and highly-innovative approach, coupled with their careful monitoring and integration of all processes ensures the most effective and efficient packaging solution.