NDC International offers the following Solder Ball Placement systems from KOSES:

KOSES Flux Pre-Cleaning System KPM300

FEATURES

- Dual Rail Flux Pre-Cleaning System

- Multiple Function System for Cleaning: OSP Pre-Cleaning & Via Cleaning

- High Productivity

- Reliability & Quality

- Flux Dotting for OSP Removal on Bottom Ball Pad

- Provides Optimized Blade Angle

- Parameter Setting for Station Block Height Control Prevents Material Damage

- Strip Warpage Compensation

- Reliable Flux Auto Supply & Management

KOSES KAM7000F Solder Ball Attach System

FEATURES

- New Solder Ball Mounting System for Singulated Packages Handles Wide Boat Flux Dotting & Ball Attach in 1 Shot

- B.P.M. for Wide Boat is Approximately 2 Boat

- Cycle Time for 1 Boat Under 29 Sec.

- Mechanical Clamp Increases the Applicable Package Quantities in a Boat

- Package Alignment Using Mechanical Alignment Classified by Normal Package & Heat Spread Type

- Normal Package Uses Bottom Guide Concept to Achieve Accurate Alignment

- Heat Spread Uses Top Guide Concept to Achieve Accurate Alignment

- Applicable Min Ball Diameter: 0.2mm, Min Pitch: 0.4mm

- Diameter of 0.2 Ball Can Use 2-Step or 3-Step

- Vision Inspection is Optional for the Offloader (Model: KUM4000F)

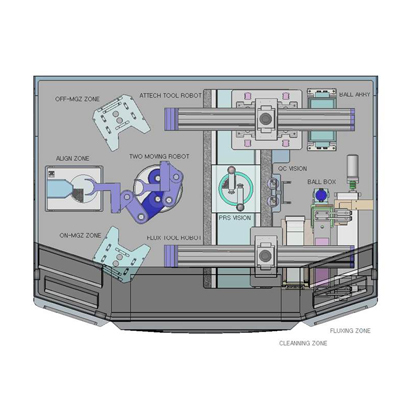

KOSES KWA 970 Wafer Solder Ball Attach System

FEATURES

- Interchangeable Loader/Off Loader According to User Selection

- 6 ~ 8-inch Wafer Application

- Easy-Access Design

- Robot System Handles Wafers at 8 Points in 340 Degrees

- Soft & Precise Movement Prevents Wafer Damage

- Optional Pre-Alignment System

- Transfer Arm with Sensor to Identify the Wafer

- X, Y, θ Table Controlled by PRS Vision System

- PRS Vision System Checks Wafer Surface to Provide Wafer Aligning Data

- Flux Mask Printing System Ensures the Exact Flux Volume and Flux Position

- Individual Vacuum Control System Allows Ball Placement on the Wafer Edge Corner

- Pre-Vision and Post Vision to Verify Accuracy