PINK GmbH Thermosystems, founded by Friedrich Pink, is located in Wertheim / Main, Germany. The product range includes systems for vacuum-supported soldering, sintering systems, low-pressure plasma systems for surface treatment as well as systems for drying and processing technology.

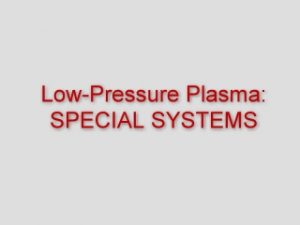

Low-Pressure Plasma System: Model V6-G

FEATURES

The standard unit V6-G is designed as a tabletop device for industrial small series production as well as for low-pressure plasma treatment in R&D laboratories. It can be used for surface treatment processes, cleaning and activation.

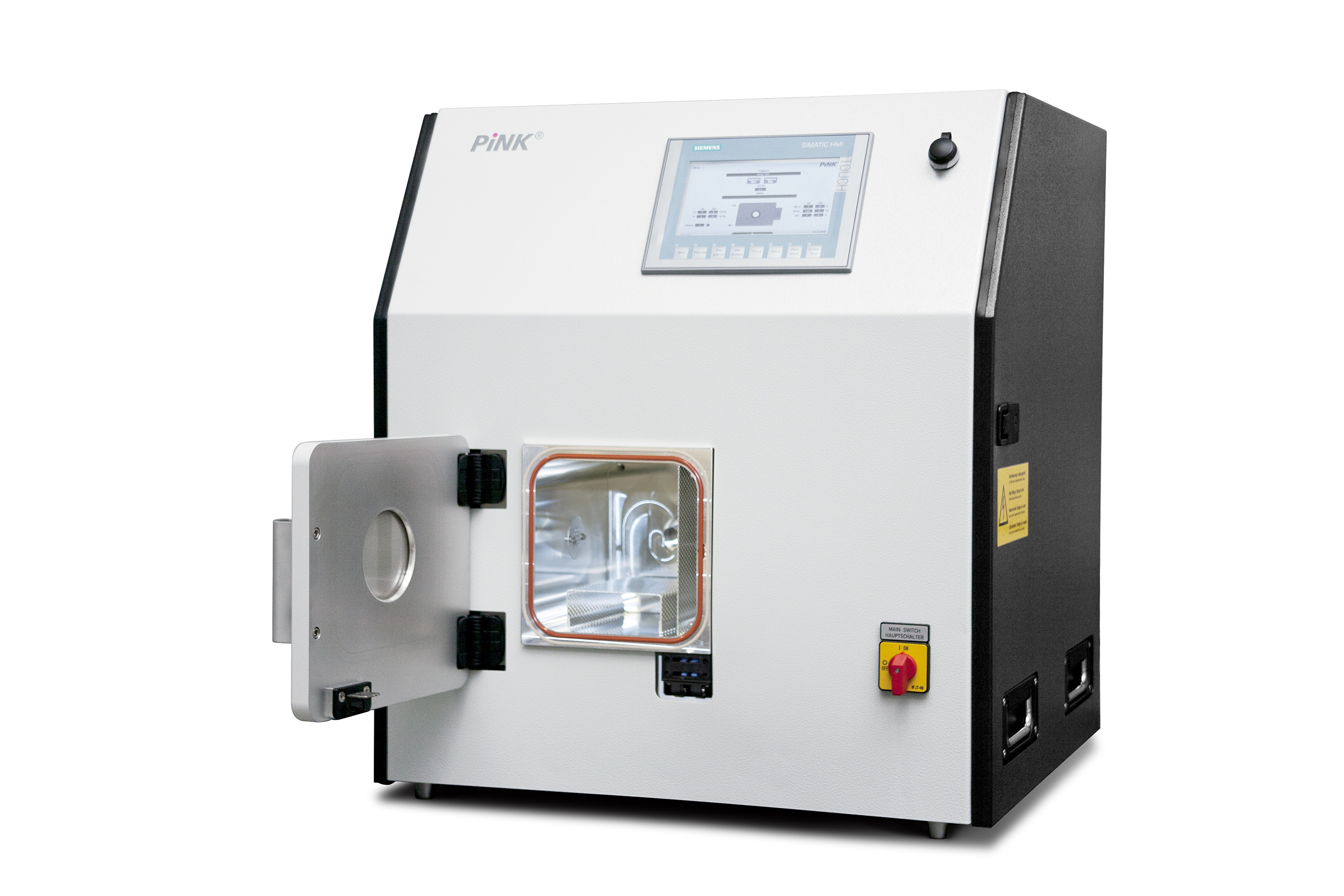

Low-Pressure Plasma System: Model V10-G

FEATURES

The efficient batch system V10-G is designed for the removal of photoresists. In addition, it can also be used for wafer cleaning.

Low-Pressure Plasma System: Model V15-G

FEATURES

This system is integrated in a 19” rack which is equipped with rollers and height-adjustable feet. A professional PLC control unit serves as storage for definable process parameters.

Low-Pressure Plasma System: Model V55-G

FEATURES

- This system is integrated in a 19” rack which is equipped with rollers and height-adjustable feet. A professional PLC control unit serves as storage for definable process parameters.

- The V55-G model offers a bigger chamber and more microwave power compared to the V15-G model, plus a Baratron vacuum gauge. (The V15-G has a Pirani vacuum gauge.)

Low-Pressure Plasma System: Model V80-G

FEATURES

- The system V80-G is suitable for industrial production as well as for R&D applications in the laboratory sector.

- The integrated professional SPS control serves as storage for definable processes and parameters.

Low-Pressure Plasma: Inline Systems

FEATURES

- In order to exploit the advantages of plasma technology in industrial series production, PINK offers customized solutions enabling its systems to be integrated into existing or new production lines.

- The technical features are individually configured to match customer requirements, enabling the plasma process to be applied fully automatically and with maximum productivity.

Low-Pressure Plasma: Reel-to-Reel Systems

FEATURES

- The reel-to-reel technology is a method especially developed for the plasma treatment of flexible tapes. The tape is continuously rewound from one reel to the other during the treatment. Transportation speed depends on the type of plasma process.

- Plasma processes used for tape-shaped substrates are e.g. etching, activation, coating and cleaning. Plastic films as well as metal strips like lead frames can be processed. The processing of reel with interleaf (protective foil) is also possible.

Low-Pressure Plasma: Special Systems

FEATURES

- In addition to standard systems, PINK also offers customized special systems. These systems are individually designed according to customer’s requirements with regard to chamber volume, excitation frequencies and controls.

- PINK’s services include comprehensive consulting, analysis of the task and development of the ideal plasma process according to customer requirements. The highest possible productivity and reliability can be achieved even for demanding purposes.